Understanding 4x4 12v Dual Battery setups

A Dual Battery installed into the engine bay of a Late model Toyota Hilux

Redarc, BCDC, Smart Alternator, AGM… These terms are all often thrown around when talking about Dual battery setups in a modern 4x4, and it’s all too easy to get lost in the jargon of it all. Drop Bear 4x4 is here to help break it down and ensure you make an educated decision when it comes to setting up your 4x4 for portable power on the go.

First things first, what is the purpose of a Dual Battery setup in any 4x4?….

A dual battery setup in a 4x4 refers to a system that uses two (or more) separate batteries with different functions. The primary battery is used to start the engine and run the vehicle's primary electrical systems, while the secondary battery is dedicated to powering additional accessories like lights, additional accessory sockets, fridges, and other electronics when the engine is off.

The system often includes a battery management system or isolator to manage charging and prevent discharge of the starting battery. This arrangement is particularly useful for off-roading and overlanding, where additional power for equipment for prolonged periods of time when the vehicle is off (such as running a fridge over night) is often necessary. This setup ensures that the accessories do not drain the primary battery, making sure the vehicle can always start.

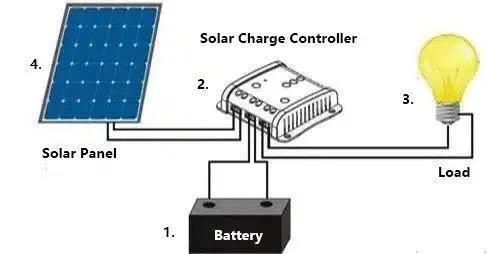

Fig 1. A diagram portraying a typical dual battery layout. This setup uses a Redarc BCDC Charger to charge the secondary battery.

Note, this system also allows inputs for solar panels to allow for additional methods of charging the secondary battery

the BCDC charger

A Battery Charger DC to DC (BCDC) charger is crucial in a dual battery system, ensuring that your secondary battery is effectively charged to a full 100% while driving. BCDC chargers are highly efficient and operate by converting your vehicle’s DC voltage to the optimal level required to fully charge the auxiliary batteries, regardless of their type. These system often include multi stage charging, like those found in conventional workshop chargers to break down Sulfation within the plates on the battery. This helps to ensure maximum battery life & performance.

A BCDC charger is more versatile than a older style VSR (Voltage Sensitive relay) As they can be configured to charge secondary battery chemistries optimally. These batteries can often require different charging voltages to the primary battery found in the vehicle, resulting in secondary batteries being inadequately charged otherwise. These are discussed further below

In modern vehicles installed with computer controlled alternators, a BCDC charger is a must to ensure adequate charging of a second battery. This is because of the varying voltages produced by the vehicles alternator, cutting charge in and out based on a number of variables such as under bonnet temperature, engine load & RPM.

Cant i just use an Isolator?

Fig 2. This diagram shows the VSR wired inline, between the primary (starting) battery and secondary (accessory) battery. When receiving charging voltage from the main battery, the relay engages, linking the two batteries together and charging the secondary battery.

A Voltage Sensitive Relay (VSR) - also called an isolator - is a cost effective option for those looking to install a 12v dual battery system in a vehicle with a fixed voltage alternator. This relay engages when receiving voltage from the vehicles charging system and disengages when voltage drops below a pre-determined threshold. (after the vehicle has been switched off)

These are functional, reliable, and straightforward to install. Where issues arise is is when used in late model vehicles with variable alternators. Due to the inconsistent voltages produced by the vehicles computer controlled alternator, a VSR is not always engaged when the vehicle is on. This results in the secondary battery not being charged properly, leading to flat accessory batteries and reduced battery life.

A VSR, still does have its place in a modern dual battery setup with an alternative function. Due to the inclusion of an override wire (Blue Wire Fig 2.), a VSR can be manually wired to a switch to link a primary and secondary battery together as desired by the driver. This is handy in situations where the primary battery has been flattened, and lets the secondary battery serve to jump start the primary battery in emergency situations.

The deep cycle Battery

Fig 3. A conventional deep cycle battery is made using fewer, but thicker internal plates. This allows the battery to supply a smaller current for a longer duration of time, like powering a fridge or lights for hours.

This is different to a starting battery designed to supply a large amount of current in a short burst - like power the starter motor in a car.

A deep cycle battery in a dual battery system is designed to provide a steady amount of current over a prolonged period. It is built to be discharged up to 80% of its capacity repeatedly, unlike regular car batteries which are meant to provide a high current for a short duration to start an engine.

Deep cycle batteries have thicker plates and a denser active material withstand deep charging and discharging cycles. This design allows them to recover fully after being significantly discharged, which is ideal for running power-intensive accessories in 4x4 vehicles when the engine is not running.

There are various types of secondary batteries on the market, with different internal construction and chemistry to help optimize its performance in a 12v dual battery system.

Different Battery Chemistries:

Lead Acid Deep Cycle: These batteries are cost-effective and widely available, making them a popular choice for those needing reliable, low-cost solutions for frequent deep discharges. The have a similar construction to a starting battey, but using fewer, but thicker lead plates to handle smaller loads being drawn from the battery for longer periods of time.

AGM (Absorbed Glass Mat): AGM batteries are better suited for releasing small amounts of energy over longer periods. They use fiberglass matting to store their electrolyte as opposed to purely a liquid. This makes them spill resistant, durable and resistant to vibrations, making them ideal for rugged off-road use.

Lithium: Lithium batteries are lighter and have a higher energy density, offering longer lifespans and better performance per charge. They are more efficient, charge faster, and discharge deeper than their counterparts without losing capacity. They utilize a collection of battery cell packs wired together and controlled by a battery management system (BMS). They come in at a high price point compared to the other

Each type of battery offers distinct advantages depending on your 4x4 needs, whether it's for long off-grid trips, heavy-duty off-road use or in conjuntion with an additional battery system in the likes of a caravan or camper trailer. The right choice can significantly enhance your vehicle’s utility and performance on varied situations.

Shining light on solar panels

Integrating solar panels into your 12V dual battery system can greatly enhance the off grid capabilities of your 4x4, allowing you to extend your adventures without needing external power sources. Solar panels convert sunlight into electrical energy, which is then used to charge the secondary battery in your dual battery system. This setup is particularly useful for extended trips where access to traditional charging methods might be limited.

Solar panels are used with a solar regulator, or in conjunction with a BCDC charger to prevent overcharging. These also isolate the solar panel from the battery when charging is not required. This helps preventing reverse flow, a phenomenon where a solar panel drains power from a battery into itself. This can cause flat secondary batteries, for example when a vehicle is parked overnight and the solar panel is not producing electricity to charge the battery it is connected to.

Fig 4. A Diagram depicting a Solar Regulator wired into to charge a 12v Battery.

Note: in situation where a BCDC is used with a dedicated solar input, it is important to wire the direct output from the solar panel to the input of the BCDC. A regulator is not used, as the control of the solar panel is handled by the BCDC charger

As you venture into the world, ensuring your vehicle is equipped with a reliable dual battery setup can enhance your off-roading experience significantly.

Drop Bear 4x4 & Leisure is committed to demystifying the complexities of 4x4 electrical systems, helping you understand and choose the right components for your needs. From selecting the ideal battery type to integrating cutting-edge charging technology, we do our best to help ensure your setup is robust, reliable, and ready for any adventure!

Want to deep dive further into the nitty gritty of your 12v dual battery systems? Check out these links for some additional reading:

Learn about the different styles of common 12v electrical plugs

or how to properly size up and use inverters in your 12v electrical setup

Still hungry for more?

You can read up on the latest news from Readarc Electronics Australia

or check out the latest and greatest in driving lights, solar panels and recovery gear from our mates at Hardkorr!